The regulations and constraints on pharmaceutical supply chains pose unique challenges that create a heavy reliance on specialty carriers. Specialty carriers which can be extremely difficult for procurement teams to compare. These providers are often ones that have to be tendered or work on a per-quote basis. Because this tends to be more manual, these decisions are often highly relationship-based and favour incumbent providers. But that means you might be missing out on the best rates for your needs.

Specialty carriers through 7bridges

Because specialty carrier procurement and management presents such unique challenges, the need for specific functionality is clear. We solved that problem through AI and made it accessible and functional with APIs. In fact, we have pioneered the API build, and integration, with widely used carriers like Marken, Worldcourier, & QuickSTAT. With the API, we bypass email in the electronic information submission and make working with those carriers faster, smoother and more effective.

Our continuously adapting AI is always ready for changing circumstances and can integrate with your 3PL networks easily. This means your warehouse provider can use our system and UI to book shipments.

When an order is received, the AI automatically selects the best dispatch site, route and carrier for the shipment. Instead of having to do that work manually. In the platform, complex real-time predictions are factored into the selection. The types of factors you can base decisions on include:

- availability of inventory and packaging materials

- operational capacity

- carrier price and historical performance

- estimated shipping times

- the likelihood of route disruptions

- environmental impact

This capability can help you have better data, better quotes for these carriers, better customer outcomes and spend your time at work better.

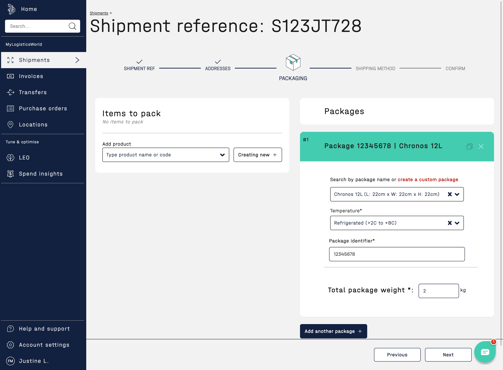

A screengrab from the 7bridges platform which showcases

A screengrab from the 7bridges platform which showcases

the specialty carrier function.

Better data

The first thing we do is consolidate all the shipment data across multiple carriers including costs enabling optimisation, reporting etc. This gives you more visibility into what working with these carriers will actually mean for you. And the integrations that we’ve created mean that we can give you more data for more suppliers than you may have had already.

Better quotes

Make more informed decisions based on properly quoted costs, instead of whichever you're most familiar with. Or most easily able to access. Using these data-driven quotes, the choice of the most effective carrier can be made. And to make that easy, these are presented in a user-friendly way to allow like-for-like comparison. This gives users the power to compare rates and choose in an informed way.

With this specialty carrier function, you can ensure that you always work with carriers that can help fulfil particular needs like shipping in specific temperature conditions, specific packaging, or other specific requirements for transporting. This helps remove the need for complex rate cards and databases.

Better customer outcomes

Temperature-controlled shipments often have strict timelines associated with them as well. And they often have a direct impact on customer needs and patient outcomes. This feature of the 7bridges platform helps ensure better outcomes for both by making the process more efficient and ensuring that the shipment arrives at the date and temperature it needs to.

For temperature-controlled shipments, you can specify packaging types and temperature ranges, making sure there’s clarity for the providers around which service is being requested. This keeps your orders arriving in the specified conditions, on time, at the lowest price and even with a reduced carbon footprint if that’s a factor you include. Plus, you can use this feature for tracking. If you want, it can also be white-labelled, so you can communicate with your customers and help them receive shipments in a way that makes sense for them.

Better time spent

More efficient processes mean going from manual email processes to automated processes where data is passed electronically to the providers. This creates operational efficiencies by simplifying the process of preparing and sending orders.

An intuitive user interface guides warehouse and site staff through the packing process, and helps them to minimise material waste and package sizes. From there you can automate your shipment booking processes from start to finish - selecting a carrier, generating labels and ensuring cross-border documentation is met.

On top of that, your team can immediately retrieve the most up-to-date information about your shipment. It doesn’t matter which site the order originates from, the supplier that’s carrying it, or the region it’s traversing.

All of these things together help create a smoother, more effective supply chain. The platform takes processes that were previously manual and lengthy and automates them, giving your team more time to act and more room to think.

So, for supply chains like yours where specialty carriers are a complicated necessity, there may be a better way. Using data and APIs to make sure you have the right product going to the right person at the right time and the right temperature. Taking this approach can help you drive better outcomes for your supply chain, your business and, ultimately, your customers.

Want to find out more about how we’re helping pharma supply chains procure specialty carriers smarter? Get in touch.