Managing supply chain invoices is still a surprisingly manual process. Records are kept in spreadsheets, individual team members spot-check individual invoices and errors slip through the cracks and start to build up. With what it takes for supply chains to run these days, keeping on top of every single invoice from each supplier and each delivery is impossible. It’s a seemingly endless task, but what else can you do?

Well, more than you think probably.

The first step toward solving the problem of invoice overwhelm is understanding just exactly how you got to this point. You know that there are better, more effective ways to manage your invoices out there, but, right now, you’re facing hurdles that keep you from getting there. What you might not realise is how important gaining that baseline view of your data really is.

Learn more: Are you leaving millions on the floor by ignoring AI?

What gets in the way

Lack of resources

One of the main problems we see companies come up against is a lack of resources. Particularly in terms of manpower and IT expertise. Invoices can create an absolute deluge of data from delivery and charge information. When used well, this data can be used to make smarter decisions about how best to move your goods. Unfortunately, teams often have too much incoming data to review and analyse manually.

Lack of IT resources, on the other hand, usually means there is a separate IT team and supply chain optimisation isn’t a priority project for them. That means only projects with no IT set-up are viable for many supply chain and logistics teams.

Complex dispute processes

With most providers, dispute processes are lengthy and not an efficient use of people’s time. The cost of time spent chasing and creating disputes manually can counteract a surprising amount of the returns. We have found that at least 3-5% of logistics spend is lost and can swiftly be recouped by a more effective disputing of charges.

Read more: How invoice auditing works with 7bridges

Managing providers

Gaining control over suppliers is a significant challenge. This is true regardless of how many relationships you’re trying to manage. Of course, one way that organisations can get the best rates from third-party providers is to use a multi-carrier strategy.

However, managing more than one provider adds levels of complexity. For some, the manual effort needed to stay on top of multiple providers can be overwhelming. Especially if you are struggling to ensure you’re getting the level of service you’re paying for.

This is especially true when it comes to managing all of the data that comes with multiple providers. One obvious example? Next-day shipping. What does that really mean? It can be something different for every carrier. And that means you're going to really struggle with using your data.

In the 7bridges platform, we solve that problem through General Ledger (GL) coding. We set up the data from your various providers so that they can be compared in a way that makes sense and you don't feel like you're comparing DPD's apples to DHL's oranges. And for supply chains that have really specific needs, we can even create custom codes to make it all flow seamlessly.

No baseline data

Not having baseline data to compare your logistics performance to can have far-reaching impacts. We’ve seen up to 20% cost and service variance between carriers. That means companies without an effective way to baseline or standardise can lose out without realising.

It also means there is no clear foundation for digitalising and future-proofing your supply chain. Your baseline data is what tells you whether or not your supply chain is performing to the standard you need it to. And getting that right is the first step in being able to take meaningful action. This data can help you identify all sorts of discrepancies, from duplicate invoices to being charged for delivery timelines that your providers aren't living up to.

Check out our baseline and benchmarking layer to learn more!

Once you have your baseline data in place, you can also use the global benchmarking data within the 7bridges platform to see how your supply chain performance stacks up in the market. Which means you'll have even more tools available to know whether or not you're really getting the performance you're paying for.

What you can do about it

Increase manpower

One, fairly straightforward, solution is to grow your team. More people means more availability for managing your invoices and provider relationships. With more people on your team, you can check and dispute more invoices, better manage your providers and, possibly, help optimise. Though that part may be complicated depending on your procurement process and who manages your provider relationships.

That said, this solution doesn’t necessarily help you define your baseline data or prepare your supply chain for the future in other ways. And it isn't the most efficient. We've seen supply chain teams that have a whole person or even team dedicated to this endeavour. And it rarely makes for an effective way to do things.

Invest in your future

Alternatively, you can start resolving all of those issues and even see returns instead of just more costs. Investing in your data and supply chain tools can give you rapid results with surprisingly little effort from your end. Instead, you can let a platform like 7bridges do the heavy lifting and start having real, usable data to make decisions with.

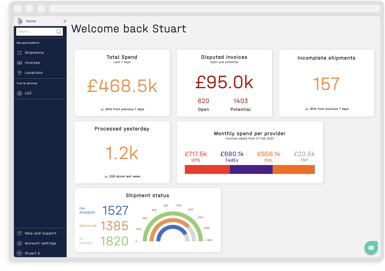

Getting control of your invoice data increases the overall visibility of your logistics performance. It offers a holistic view of supplier performance and costs and creates a baseline layer of data on which to base decisions.

For example, the 7bridges baseline and benchmarking layer ingests your invoices, establishes your baseline figures and then can nearly immediately start identifying opportunities. For example, letting you know whether or not paying too much for the levels of supplier service you’re receiving. Customers using the invoice auditing aspect of the baseline and benchmarking layer reduce carrier variances of up to 20% immediately and show a 3-14% improvement in costs from current providers.

On top of all that, this is the perfect first step for reinventing the way you approach your supply chain. While making changes and seeing ROI through audit functionality, you can also be building a path to even greater value. Beyond getting your data in order, you can start exploring simulations for better procurement or scenario planning, or you can move on to automating processes that slow you down. But it all relies on data first. And for supply chains, that means getting your invoices back in hand.

So, even though your invoices feel like huge time and resource sink right now, they don’t have to be. Investing in a quick win, and resource-light solution to enable you to take the first step towards making your supply chain really work for you and your business.

Want to know more about how we sort out your invoices here at 7bridges? Check out this whitepaper all about our baseline and benchmarking layer or contact one of our experts here.